Natural Hydrogen

Production

Natural Hydrogen

Production

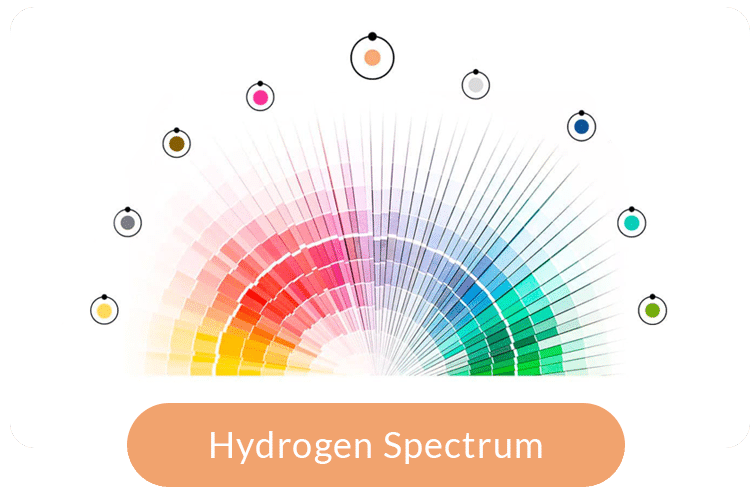

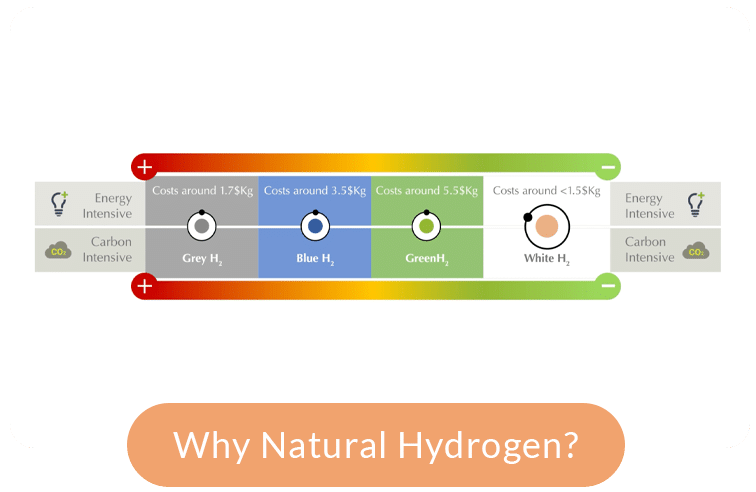

Renewable, natural-occurring “white” hydrogen may become the cleanest, lowest-carbon emitting and most cost-effective driver in the energy transition. Engineers, geoscientists and Oil & Gas experts are working to better understand geological hydrogen’s subsurface behavior and drive local, safe and sustainable production from there.

Solutions are needed for all parts of the process; from exploration, development, production, storage and transport, right through to the utilization of hydrogen. Hethos is focusing its expertise on developing all key elements of hydrogen production, from reservoir study to well design; materials used; and surface safety.

Hethos has already defined a full range of hydrogen production technologies and is working on technical and scientific solutions to optimize natural hydrogen production.

Renewable, natural-occurring “white” hydrogen may become the cleanest, lowest-carbon emitting and most cost-effective driver in the energy transition. Engineers, geoscientists and Oil & Gas experts are working to better understand geological hydrogen’s subsurface behavior and drive local, safe and sustainable production from there.

Solutions are needed for all parts of the process; from exploration, development, production, storage and transport, right through to the utilization of hydrogen. Hethos is focusing its expertise on developing all key elements of hydrogen production, from reservoir study to well design; materials used; and surface safety.

Hethos has already defined a full range of hydrogen production technologies and is working on technical and scientific solutions to optimize natural hydrogen production.

Production

Technologies

Hethos has access to a full range of production technologies and, through innovation, the expertise to solve the challenges of hydrogen and helium extraction

Hover over the technology to find out more

Reservoir simulation

- Current simulation systems are being adapted for hydrogen reservoirs

- Collaboration with Ohio State University to develop a hydrogen based simulator using their existing CO2 model

- Easy to adapt to another reservoir, and insert large macro-specifics such as faults etc

Hydrogen adapted seismic

- Targeting hydrogen chimneys and local accumulations, especially at the intersection of large faults and unconformities

- Will use P versus S waves to identify hydrogen chimneys with 3S Seismic

- Discussions with other teams such as Geolink or Wavelab

Polymer casing and tubing

- Metal alloys casing and tubing will not resist hydrogen embrittlement, and current plastic casing does not resist lower than 500m to 700m

- Hethos will use a polymer that can resist downhole temperatures and pressures down to 2,000m at least

- Casing and tubing are saline water and hydrogen resistant

Well architecture

- For transit reservoir with local accumulations, Hethos targets the hydrogen flux with multi-level laterals placed on both sides of the perpendicular of main local fracture direction

- Laterals can be done by radial drilling, or more classical techniques such as whipstock which is less expensive than horizontals as lower precision needed

Sensors

- All weather, wide detection range hydrogen sensors are mandatory for surface crew safety. Existing sensors have poor resistance to outside conditions and limited sensitivity range

- Developing sensors for ‘fairy circle’ analysis

- Hethos will use customized sensors based on semi conductors, answering the above issues

Production

Technologies

Hethos has access to a full range of production technologies and, through innovation, the expertise to solve the challenges of hydrogen and helium extraction

Tap on the technology to learn more

Reservoir simulation

- Current simulation systems are being adapted for hydrogen reservoirs

- Collaboration with Ohio State University to develop a hydrogen based simulator using their existing CO2 model

- Easy to adapt to another reservoir, and insert large macro-specifics such as faults etc

Polymer casing and tubing*

- Metal alloys casing and tubing will not resist hydrogen embrittlement, and current plastic casing does not resist lower than 500m to 700m

- Hethos will use a polymer* that can resist downhole temperatures and pressures down to 2,000m at least

- Casing and tubing are saline water and hydrogen resistant

Sensors

- All weather, wide detection range hydrogen sensors are mandatory for surface crew safety. Existing sensors have poor resistance to outside conditions and limited sensitivity range

- Developing sensors for ‘fairy circle’ analysis

- Hethos will use customized sensors based on semi conductors, answering the above issues

Hydrogen adapted seismic

- Targeting hydrogen chimneys and local accumulations, especially at the intersection of large faults and unconformities

- Will use P versus S waves to identify hydrogen chimneys with 3S Seismic

- Discussions with other teams such as Geolink or Wavelab

Well architecture

- For transit reservoir with local accumulations, Hethos targets the hydrogen flux with multi-level laterals placed on both sides of the perpendicular of main local fracture direction

- Laterals can be done by radial drilling, or more classical techniques such as whipstock which is less expensive than horizontals as lower precision needed